Supercritical Assisted Atomization

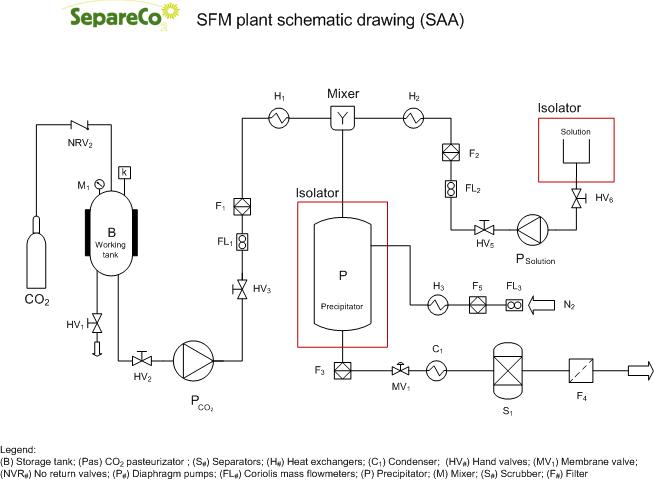

SAA (Supercritical Assisted Atomization) process is focused on the nebulization of the liquid solution rather than using dense gas (SCF) to achieve precipitation by solubility reduction for the solute to be micro- or nano-sized. At first, the solute is dissolved or suspended in aqueous or organic solvent or their mixture and then mixed intimately with near critical or SC by pumping both fluid through a near zero volume tee to generate an emulsion. The resultant emulsion is rapidly expanded through a flow restrictor to near atmospheric pressure to form aerosol consisting of micro droplets and micro bubbles. The aerosol is formed due to sudden dispersion of the liquid solution caused by rapid expansion of compressed gas. The drying chamber is filled with heated air or nitrogen gas to maintain the desired temperature for rapid drying of aerosol droplets or micro bubbles. Dry particles are collected on a filter placed at the outlet of the drying chamber.

Parameters influencing the particle formation are flow rate of solution percentage of dissolved or suspended substance, inner diameter flow restrictor (50-175 μm), temperature of the drying chamber, residence time of droplets or micro bubbles (as micro bubbles are dried faster than droplets). This process is also known as CAN-DB (Carbon dioxide Assisted Nebulization with Bubble Dryer). The SAA process differs for the use of a saturator to enable a better mixing of the supercritical fluid with the solute containing the product before it is injected into the precipitator. Generally the saturator is made with fillings for generating a large exchange surface. Others use the principle of cavitation to achieve the same result.